After waiting months for a coveted Fujifilm X100VI, they tore it apart – and found a surprising design inside the camera’s guts

Try not to cry as you watch this X100VI come apart piece by piece – there's actually some great insight in this video

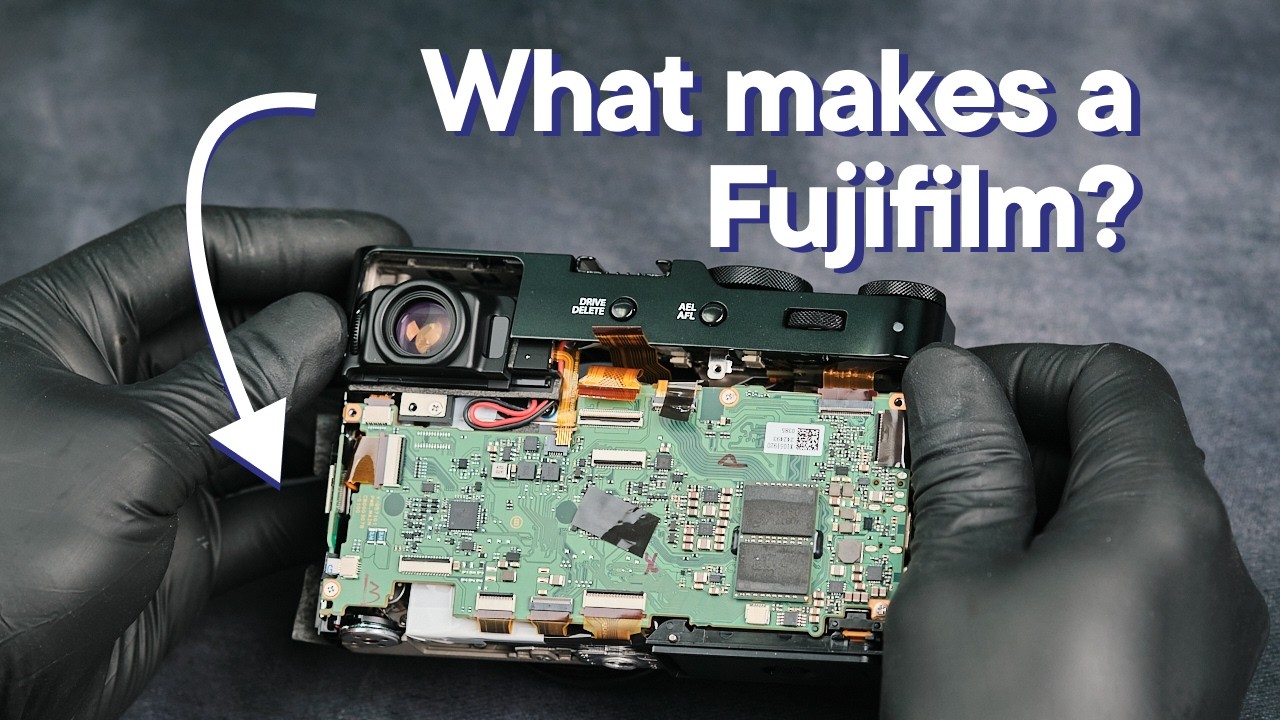

The Fujifilm X100VI is so hard to find that used models are going for more than the brand new list price – but when Kolari Vision finally received theirs after placing an order in February, they immediately tore it apart to find out what was inside. The Fujifilm X100VI teardown revealed a printed circuit board mounted right behind the sensor, a design that Kolari Vision said they’ve never seen before in their teardowns before.

Kolari Vision is a company specializing in infrared photography equipment – tearing apart cameras is part of what they do as they convert existing cameras for use in infrared photography. (Hopefully that means they can put this poor destroyed X100VI back together.) Still, watching the coveted X100VI compact camera come apart piece by piece reminded me a bit of the time I got to see the behind-the-scenes areas of Disney World – the magic feels a bit less magical.

What the teardown revealed, however, was a printed circuit board integrated right behind the sensor. Kolari Vision notes once they pulled the sensor module out they realized the circuit was integrated with the sensor itself.

It’s no surprise that the X100VI sensor has a radically different design than the X100V, after all, as the older camera has a 26MP sensor where the newest generation offers 40MP. But what I found most interesting is that when Kolari Vision did a teardown of the Fujifilm X-H2, a mirrorless camera with 40MP, it didn’t have the same integrated circuit board design.

Both cameras list the X-Trans CMOS 5 HR sensor in the specifications, so it’s a bit odd that the sensors looked so different between the two cameras. Fujifilm says that the 5 HR sensor uses “an enhanced image-processing algorithm that boosts resolution without compromising the signal-to-noise ratio.” In other words, the new design allows the camera to shoot at a higher resolution with less noise than the company’s previous designs.

With both the mirrorless and compact camera sharing identical sensor specifications as well as the same burst speeds, I suspect the integrated circuitboard design has more to do with the X100VI’s compact design compared to the larger mirrorless camera. The company also noted that, as a compact camera, the X100VI was more straightforward and simple than taking apart a mirrorless camera.

You may also like

Don't want to wait for a Fujifilm X100VI? A mirrorless camera with a pancake lens may be a viable replacement, or take a look at these X100VI alternatives or the best Fujifilm cameras.

Get the Digital Camera World Newsletter

The best camera deals, reviews, product advice, and unmissable photography news, direct to your inbox!

With more than a decade of experience reviewing and writing about cameras and technology, Hillary K. Grigonis leads the US coverage for Digital Camera World. Her work has appeared in Business Insider, Digital Trends, Pocket-lint, Rangefinder, The Phoblographer and more.