Japanese boffins have developed a working bendable image sensor!

Designed to improve image quality in the corners of frame, curved sensors could work wonders in camera phones

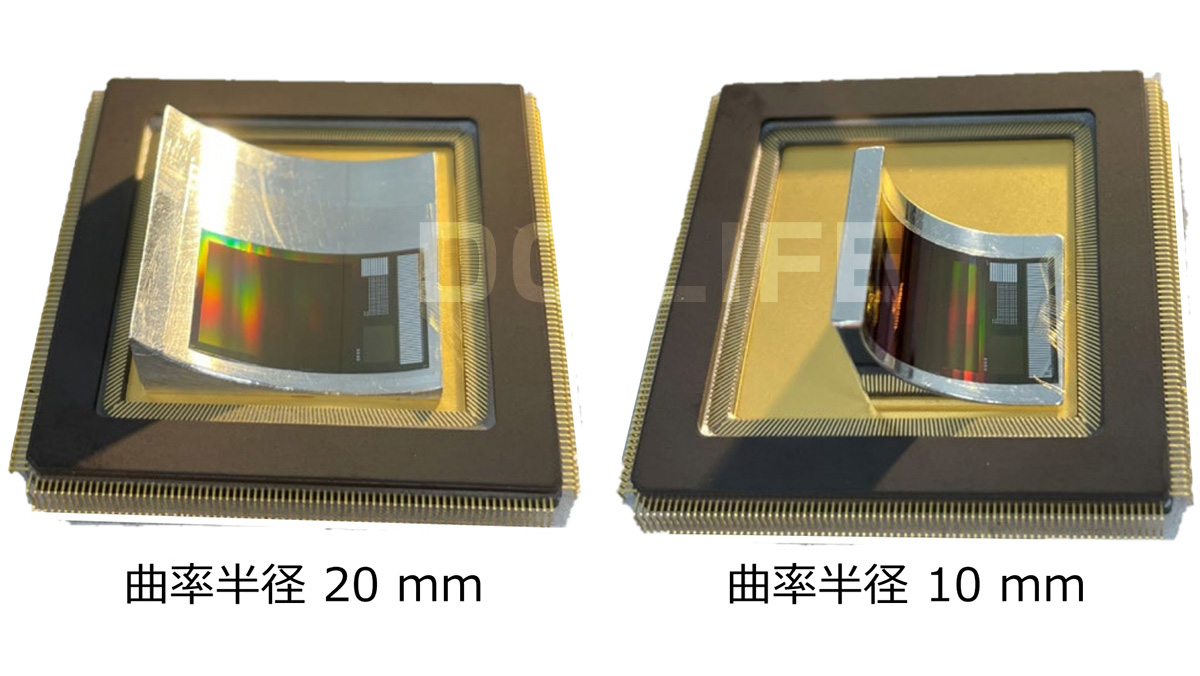

NHK Science & Technology Research Laboratories - a division of the Japanese Broadcasting Corporation - has developed an ultra-thin, bendable image sensor. Measuring just 0.01mm thick, the 320 x 240-pixel sensor is the world's first bendable silicon image sensor. This isn't the first time we've heard about curved image sensors - Sony was filing patents for curved sensor tech in 2021 - however this was far from a working prototype.

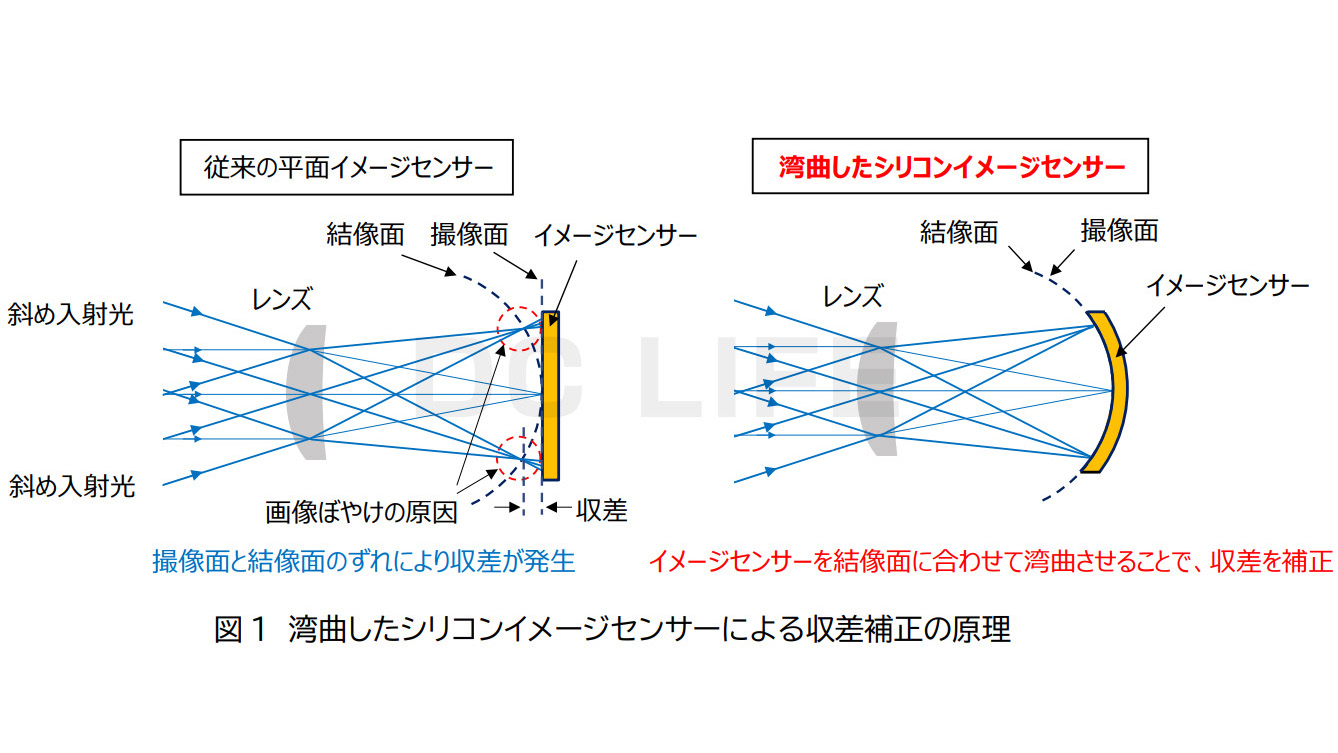

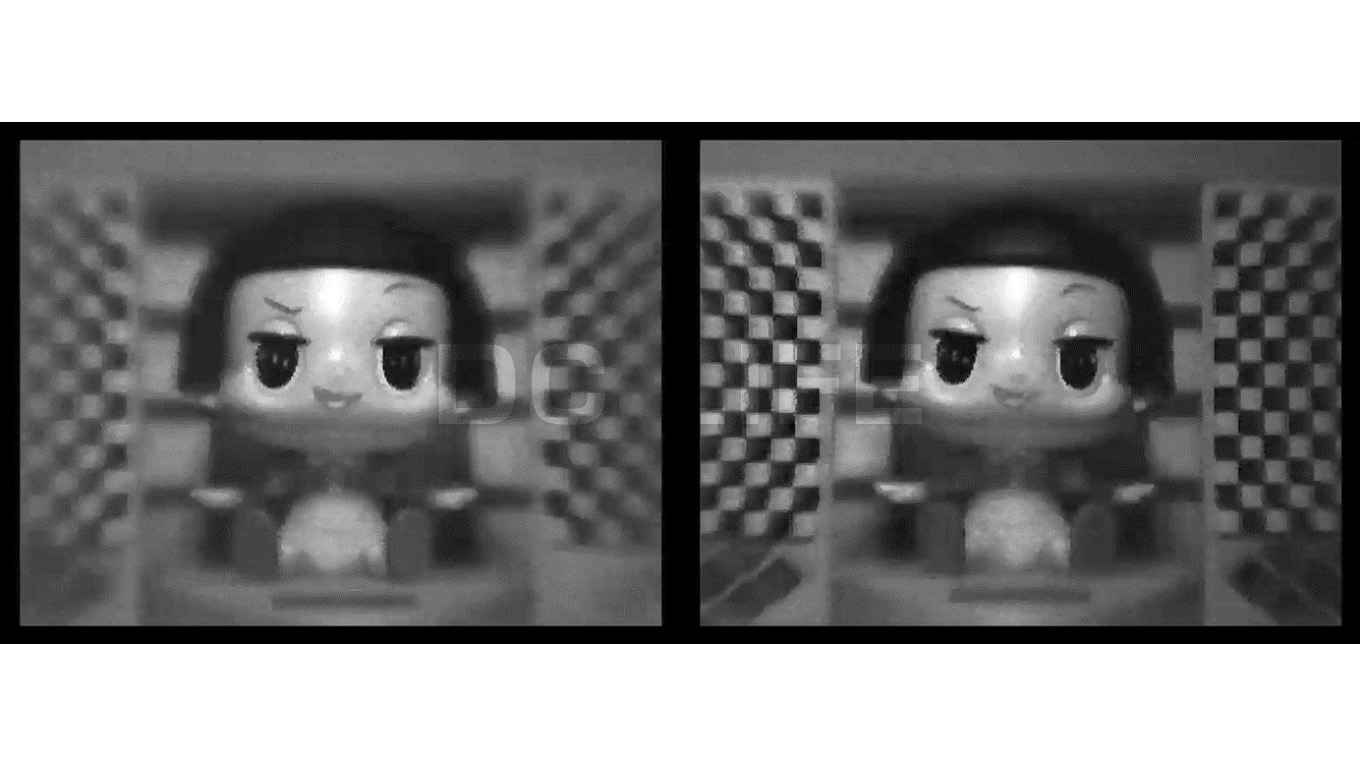

But why even bother to make a bendable sensor when current flat sensors already do a great job of capturing digital images? The aim here isn't to have a sensor that can be repeatedly bent back and forth like a foldable phone screen, but rather a sensor that can be bent into a fixed concave shape. This then enables the sensor to better capture incoming light from a lens, increasing corner sharpness and reducing chromatic aberration. By curving the sensor, you end up with a set-up far closer to the concave surface of the retina at the back of the human eye, perfectly optimised to capture incoming light from a lens.

According to NHK, conventional sensors cannot be bent like this due to their silicon substrate. NHK has apparently got around this issue by "using a special structure that inserts a thin oxide film between the silicon substrate and the silicon device layer". This substrate can then be removed using a chemical reaction, after which the sensor can then be bent into the desired concave shape.

While the theory behind this sounds compelling, its real-world use cases may be more limited. Modern cameras already have chromatic aberration reduction processing built into their firmware, and this does a great job of compensating for fringing. As for peripheral sharpness; high quality lenses for interchangeable lens cameras maintain levels of corner sharpness that, while usually somewhat lower than the sharpness in the center of frame, are still sharp enough for the difference to generally go unnoticed by the human eye.

We'd wager that a bendable sensor would be of most use in a camera phone, where there simply isn't space for big, multi-element lenses that provide the best image quality. By installing a bendable sensor, the sensor could compensate for the image quality compromises incurred by the small, simple lenses required by super-slim camera phones.

Currently this bendable sensor is in the early stages of development, hence its low resolution and monochrome output. However NHK plans to move forward with producing a color version, with the eventual goal of "commercializing a small, lightweight, high-image-quality wide-field camera by around 2030".

Story credit: NHK Science & Technology Research Laboratories

Get the Digital Camera World Newsletter

The best camera deals, reviews, product advice, and unmissable photography news, direct to your inbox!

Ben is the Imaging Labs manager, responsible for all the testing on Digital Camera World and across the entire photography portfolio at Future. Whether he's in the lab testing the sharpness of new lenses, the resolution of the latest image sensors, the zoom range of monster bridge cameras or even the latest camera phones, Ben is our go-to guy for technical insight. He's also the team's man-at-arms when it comes to camera bags, filters, memory cards, and all manner of camera accessories – his lab is a bit like the Batcave of photography! With years of experience trialling and testing kit, he's a human encyclopedia of benchmarks when it comes to recommending the best buys.